Board Edgers & Board Optimizer

Our Systems are Compatible with All Makes and Models of Carriages.

Features

- PC program will have board tally for printing:

- Piece count

- Operational screens

- Wane allowance inputs

- System Parameter entry screen

- Board Breakdown based on value in dollars per piece or volume

- Proprietary board solution software

- Ability to adapt to changing market requirements.

- PLC machine control:

- Lug chains

- Infeed rolls

- Press rolls

- Edger roll sequencing

- Pickers

- Enclosures and consoles are UL inspected

Top Scan Only

- Laser spots are on one-inch centers

- Better scan density for snapshot of boards. This increases the best solution for the board

- High speed data gathering using ethernet 100baseT

- Low power requirements for heads

PLC Screen Features

- Display status of mechanical system

- Time delay data entry for machine functions

- Machine cycle time

- Optimizer infeed and edger feed speeds

- Some operational features are displayed on the help screens

- Input / output status is displayed on the I/O screen

- Servo Sensor status is displayed on screen

- The run screen will also show a trouble message if a problem occurs with the system

PC Screen Features

- Display the axis motion status, target and actual position

- Graphic display of the board solution

- Run screen will show machine status

- System configuration data is entered through a keyboard/mouse

- 100BaseT ethernet interface

- 10BaseT ethernet interface

System Operation

- Operator will turn boards wane up and position on lug chain

- Operator will have a remote station at the location for manual machine control function

- Board will pass through scanner for solution

- If the Infeed table is ready, the board will continue onto the table, the cylinders will position the stops, and the board will feed.

- When the board clears the cylinder stop closest to the edger, another board will be delivered to the table for feed

- The rear pickers will come up for the saw pockets used

- The expected pieces per minute will be 32 peak and 28 average. This is all dependent on the mechanical ability of the optimizing table and the operator

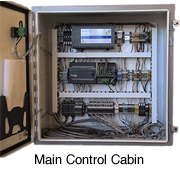

System Hardware

- The system control cabinets, operator panel, and j-boxes are pre-wired at the factory

- All cables are labeled and cut pigtails are left at the terminal blocks of each enclosure

- Rewiring of the enclosures is expedited because the colored wires and pairs are left as they were when tested at the factory

- Each enclosure has an identifying placard on the front of it

- The operator console overlay is reverse engraved, to prevent wear and tear over the years of operation

- An interconnect cable diagram is provided as well as an installation/operation manual

- The manual is written to cover most operational procedures and installation requirements